Captive care

At present, most commercial laying hens in the world are raised in captivity. Almost all intensive chicken farms in China use cage farming, and small chicken farms also use cage farming. There are many advantages of cage keeping: the cage can be placed in a three-dimensional manner, saving the ground and increasing the density of breeding; Convenient for mechanized and automated operations, with high production efficiency;

Less dust, clean egg surface; High feed efficiency, good production performance, low nesting ability, and few egg pecking phenomena; Easy to observe and capture. Disadvantages of cage breeding: cage laying hens are prone to osteoporosis, fatty liver, pecking addiction, etc., which also reduces the level of Animal welfare. Overall, the benefits of cage farming currently outweigh the drawbacks, with significant economic benefits.

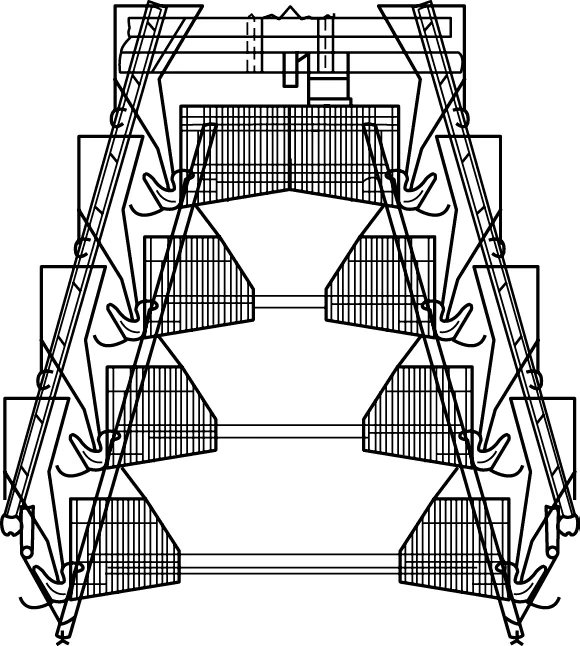

Cage rearing can be divided into stepped and stacked forms, with stepped forms being further divided into full stepped and semi stepped forms. Fully stepped with uniform lighting and good ventilation; The overlap of the upper and lower cages of the semi stepped chicken cage is 1/2, which increases the feeding density compared to the full stepped cage. The chicken manure from the upper cage is easy to fall onto the body of the lower cage chicken, and a fecal guide plate needs to be added.

Stacked cage farming is a high-density breeding method developed with the rise of land prices. Currently, the stacked chicken cage has developed to 8 layers. This type of chicken coop is equipped with an air duct at the back of the net, which directly delivers fresh air outside the house to each chicken, and can also air dry chicken manure. Feeding, drinking water, egg collection, and defecation are all mechanically operated.

Due to the increase in feeding density in the house, it is necessary to ensure appropriate ventilation and lighting conditions. The more layers, the stronger the dependence on electricity.

With the increase of mechanized feeding and automated egg collection, there is a trend for egg cages to develop towards higher levels. In this way, higher economic benefits can be achieved per unit on the ground. The size of the egg cage should meet its certain activity area, feeding position, and height, and the bottom of the cage should ensure an appropriate inclination, so that the eggs laid by the chicken can roll out of the cage in a timely manner. The size of the unit cage for laying hens is 445-450 millimeters high at the front, 400 millimeters high at the back, with a bottom slope of 8 °~9 °, a cage depth of 350-380 millimeters, and an egg collecting trough extending out of the cage of 120-160 millimeters. The cage width ensures that each chicken has a feeding width of 100-110 millimeters, and the necessary movable turning area is added according to the chicken's body shape. Each group of chicken coops is made into individual pieces with hooks attached. After the cage frame is installed, the individual pieces are hung to facilitate assembly and transportation.

Post time: Jun-27-2023